The attractive hardwood maple gets all the attention, but it’s really what’s underneath that turns sports flooring into a sports floor system. The specifications surrounding subflooring directly impact the performance, comfort, safety, and longevity of a maple sports floor.

Action Floor Systems Technical Director Don Brown has insights into what to consider as athletic directors, facility owners, and architects work with sports floor contractors to specify the right subfloor design and quality building materials.

Sports Subfloor Materials

First, Brown explains the types of building materials that are used to construct subflooring for a basketball court or gymnasium.

“The most common materials include some type of resilient layer such as a rubber or foam pad for shock absorption,” he says. “With Action Floors, for most of our history we’ve used natural rubber pads. These outlast other pad options because they don’t harden, oxidize, revert, or degrade as they age.”

Action Floors’ maple systems can include innovative solutions such our AirTech and ActionThrust natural rubber pads, featuring vertical air cells. Put simply, because of the way these pads are designed, less weight is required for compression. That means less force is needed for the cushioning effect to kick in, which delivers a higher level of shock absorption.

In fact, Action Floors’ AirTech and AirtThrust natural rubber pads require 50 to 75 percent less weight to initiate pad compression than synthetic options. Plus, they’ll continue to provide the same level of cushioning year after year.

“A natural rubber pad is considered a higher quality choice because of the longevity and consistent performance it provides.” Brown says. “Although, a foam pad is a perfectly good option for many applications as well.”

Foam padding can be helpful for sound control, for instance, especially in facilities where the gym is above the ground floor of a building.

“Then there is the structural component underneath the finished maple,” Brown continues. “Historically, it’s some form of plywood or sheathing, which can come in multiple layers and different combinations such as solid layers or strips, which are called sleepers.”

While there are subfloor designs that use either sleepers or sheathing, Brown says newer floors often use a combination of materials to maximize performance.

“You do that for performance reasons to provide flexibility and uniformity in the floor system,” he explains.

For architects, athletic directors, and facility owners looking to specify the highest quality material for a subfloor, Action Floors’ hardwood premium sheathing (HPS) works well. It’s constructed of pure hardwood and a resin that minimizes moisture migration. HPS is a durable, long-lasting building material that’s less likely to warp or bow. It’s also ideal in facilities where heavy bleachers are rolled across a gymnasium floor.

“In that situation, a material like HPS would be a good choice because it creates a monolithic surface under the maple, versus a system where there are spaces between sleepers.” Brown says.

Another option that provides dimensional stability with high resiliency is a subfloor that utilizes open cell foam padding inside grooves of the sheathing. Panel pad cushioning, which is used in our Action AnchorFlex system, protects the system under heavy loads.

Sports Subfloor Designs

The subfloor material specified for a project may depend on the type of system being installed. Brown reminds us of the three main categories of sports floor systems:

1. Floating Resilient Sports Floors

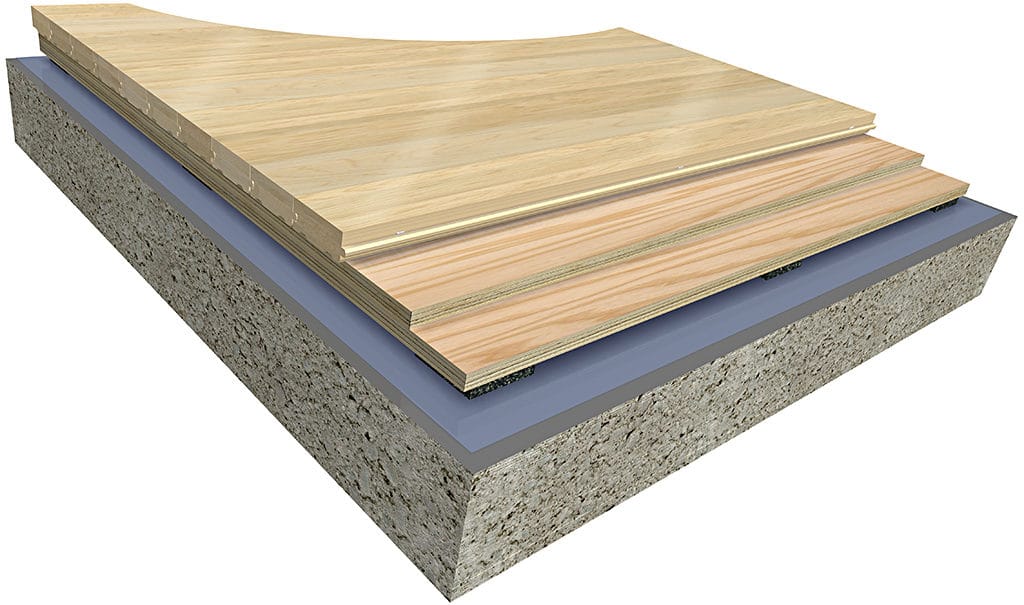

“These subfloors essentially consist of plywood or sheathing with pads on them, says Brown. “A floating floor system just rests on the concrete slab.”

Floating systems are known for their resiliency, but do not use anchors to retain the floor in place. The foam or rubber pad is what adds shock absorption and provides comfort for athletes as it deflects based on an athlete running or jumping.

ActionCush I, floating system with option for HPS sheathing

2. Fixed Sports Floors

Fixed floor systems are the opposite of floating. They are directly attached to the concrete slab using anchor pins or screws. These systems provide very little or no resilience, which means athletes won’t be getting the benefits of shock absorption.

“Sometimes fixed systems do have a pad under the maple flooring, but that’s more for sound than performance,” Brown says.

A fixed or anchored floor is considered “faster” than the more-resilient floors. That means better ball rebound but less shock absorption.

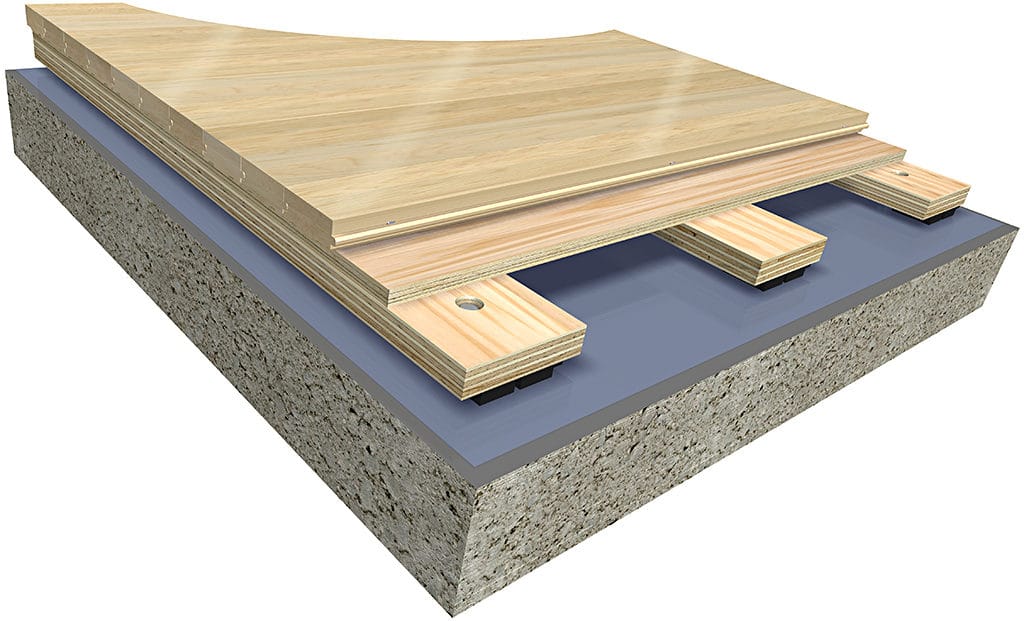

3. Anchored Resilient Sports Floors

“An anchored resilient system retains the floor to the concrete slab, but still allows the floor to move vertically and laterally,” says Brown. “It restricts the floor in a way that allows movement for performance and helps minimize vibrations while preventing bowing from moisture issues.”

Find out more about these different systems in our article on floating vs. anchored sports floors.

Action ProAir AR, anchored resilient system with sleepers and sheathing

Brown makes one other note about choosing a category of subfloor design. If it’s a replacement floor project, you’ll need to evaluate the condition of the job site, specifically the concrete slab.

“The slab depression and its condition may determine what choices are available to you,” Brown says. Ideally, the height of a finished floor will closely match that of surrounding rooms.

If the finished surface is higher or lower than floors in areas adjoining the gymnasium, you may have to install ramps or transitions in order to comply with standards in the Americans with Disabilities Act (ADA).

Subflooring and Shock Absorption

Shock absorption is usually the most important performance consideration of a sports floor system, and the design of the subfloor is the biggest factor in determining the level of shock absorption a sports floor system delivers.

“While pads provide resilience, it’s not just the pad that contributes to shock absorption,” says Brown. “It’s the placement of the pad and the construction of the layers of the subfloor. All of that affects resiliency.”

Talk to your sports flooring contractor or contact Action Floors with questions about specifying the right system for your project.

Subflooring and Sustainability

Typically, the cost of a sports floor and its performance attributes are the largest factors in choosing the right system. Cost is often directly tied to performance and the level of performance needed is usually dictated by the level of competitive play taking place on the surface. However, Brown points out that there are other aspects of sports floor materials that many architects are evaluating: sustainability and indoor air quality (IAQ).

“More and more, architects are paying closer attention to the building materials used in things such as sports floor systems,” he says. “Not only are they looking at performance, but many times they are evaluating environmental aspects of subfloor materials for sustainability and how it impacts end users.”

Action Floors is proud to make sustainability a priority. That includes our commitment to supporting responsible forestry, carbon negative certification, and FloorScore® certification. Architects and facility owners can use our exclusive SCORES™ card to evaluate the sustainability efforts of manufacturers.

When it comes to subfloor materials, the HPS Action Floors offers is made of sustainably harvested wood, and pads can be specified to be either virgin natural rubber or recycled rubber.

Action Floors’ commitment to sustainability is connected to our commitment to quality. When you specify a system from Action Floors we take steps to make sure you and your clients are satisfied with what gets shipped to and installed in the facility.

“Nearly all of our performance subfloor systems are built at Action Floors’ facility for quality control purposes,” says Brown. “So when our systems get shipped to a job site, you can expect consistency.”

Check out the wide variety of maple sports floor systems we manufacture, look for Action Floors on Sweets, and visit the Architect Resource Center on our website to download specifications and detailed drawings.